Bucknell mechanical engineering major Kade Davidheiser ’27 — who is also a member of the Bison wrestling team — was looking for a way to stay on campus this summer to further his engineering skills while also training with his fellow grapplers in the wrestling room. To do this, his summer research proposal was to design a jumping robot that could potentially be used to aid in firefighting.

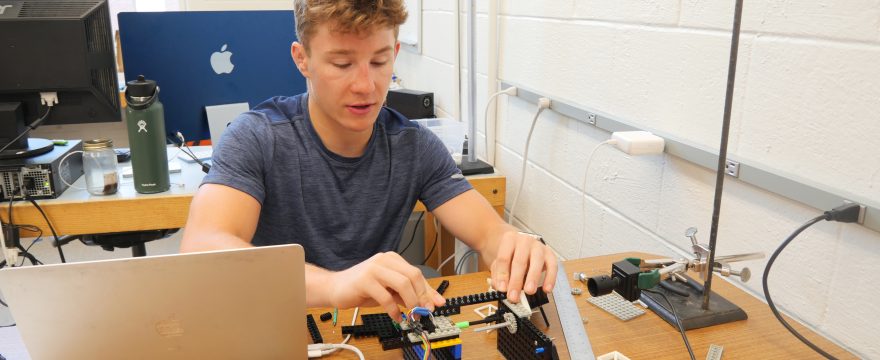

The vision for the robot includes the ability for it to traverse and jump levels, and to have a hose attachment to more easily and safely transport water into the heart of a possible fire. Davidheiser is spending 10 weeks on campus this summer developing a scale prototype, integrating Filaflex, a revolutionary flexible filament used in 3D printers.

“This is something new that has never been done before,” says Davidheiser, who is working with Professor Will Scott on this soft robotics project. “The first week we were reading tons of papers to learn what we can do and what has already been done. I have not seen anything like this.”

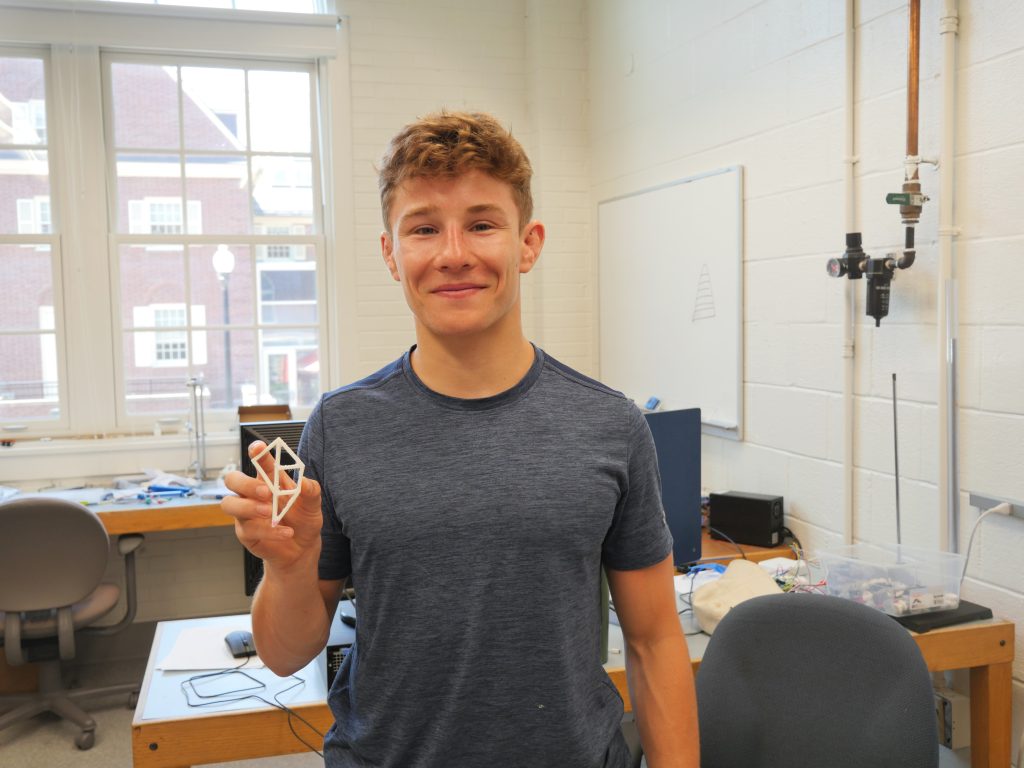

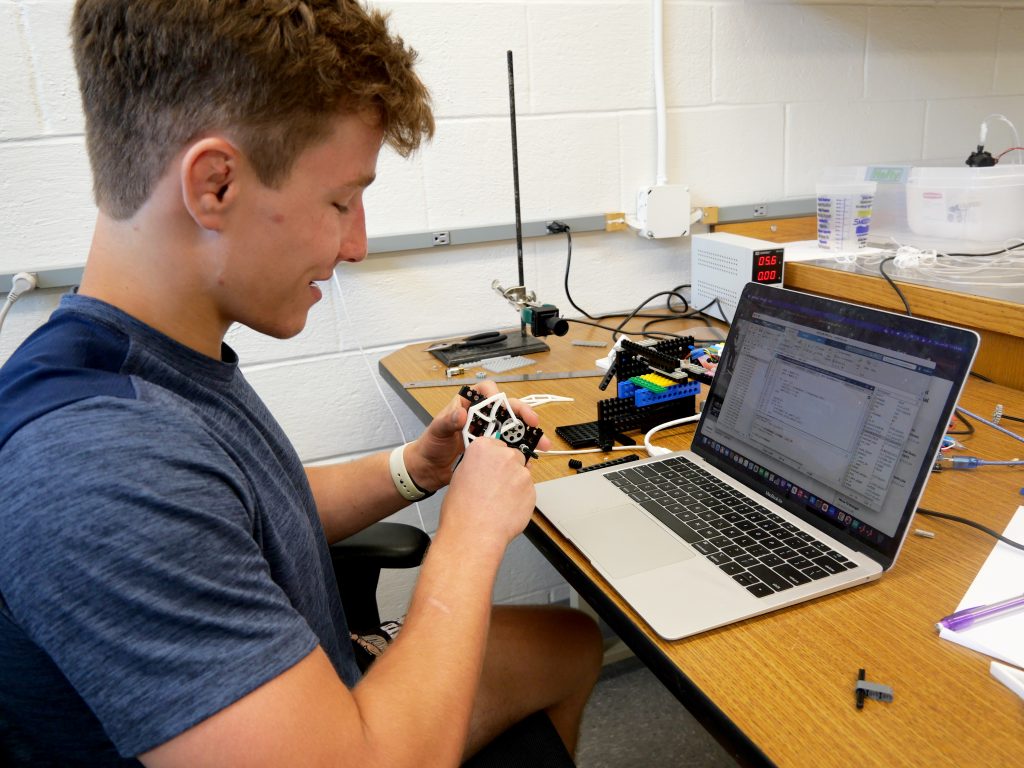

Davidheiser’s focus has been on the legs of the robot. The elasticity of Filaflex allows him to do different things, including giving the robot the ability to jump and to move forward and backward. The design of the leg is based on Dutch artist Theo Jansen’s Strandbeest walking linkage. By replacing the rigid multi-part linkages of Jansen’s design with a single flexible structure, Davidheiser’s prototype recreates the walking motion while introducing a new capability: the legs can also act as springs, enabling the robot to jump when the legs are compressed and suddenly released.

With an interest in pursuing a biology double major, Davidheiser has also tried to incorporate ideas from the animal world into his robot leg design. He’s researched frogs, insects, kangaroos and other animals that jump and has developed a tendon-based system with a wire and a crank that will look like a knee.

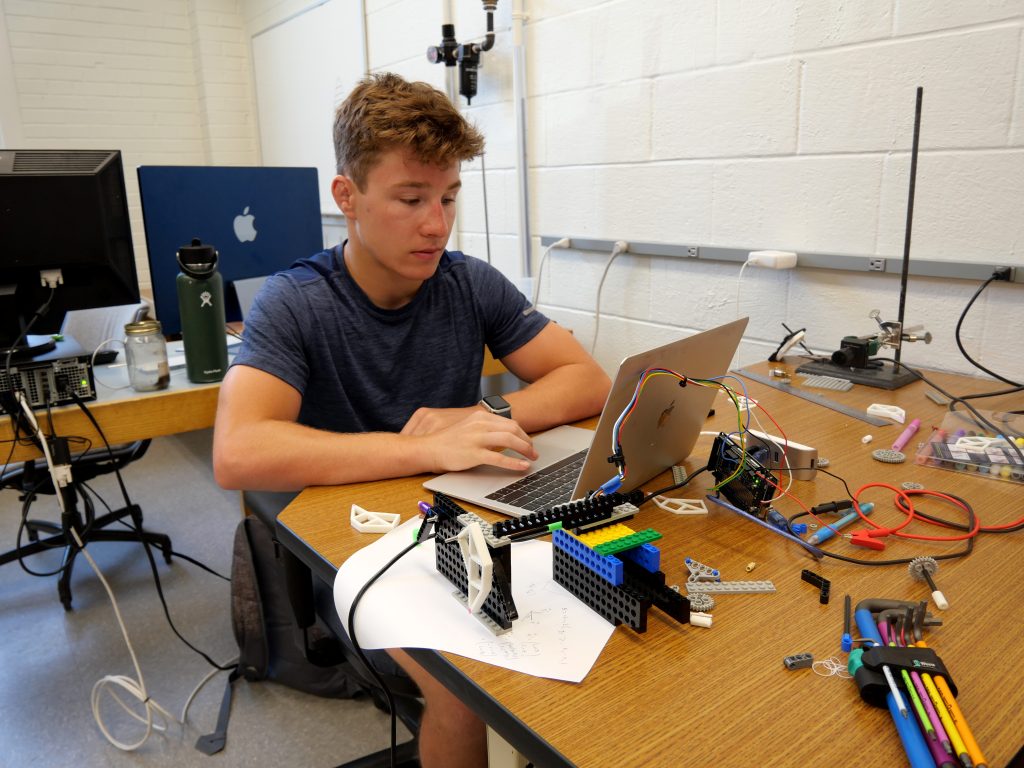

Most people probably don’t equate mechanical engineering or biology with coding, but Davidheiser has improved his coding literacy many times over this summer.

“MATLAB is very new to me,” Davidheiser says. “I didn’t have any coding experience before this year. Now I can build graphs using input numbers that I wasn’t able to do just a few weeks ago. I took a class on SolidWorks last semester and I’ve increased my skills by being able to design something like the legs of the robot. Everything is linked together. I can change one number and it moves differently.”

Davidheiser explains that his current coding challenge in MATLAB is making the legs move in a semicircle with the most points of contact with the ground or surface the robot is on. Once he optimizes the design, he’ll move forward with building the harder plastic body with motors and an Arduino to control the movement. A later prototype will likely outfit the robot in heat-resistant materials similar to what firefighters wear.

The summer has been a busy time for Davidheiser. He is up most mornings by 5:30 to get to a team lift at 6 a.m. He is in the lab on the first floor of Dana Engineering Building by 8 a.m. and then back down to the Graham Building for wrestling practice by 3 or 4 p.m. In the evenings he explores the Lewisburg area.

On the wrestling mat, Davidheiser competed in five matches in the 125-pound weight class as a rookie in 2023-24. The team finished with an 8-8 record and placed seventh out of 17 teams at the Eastern Intercollegiate Wrestling Association (EIWA) Championships, held in Bucknell’s Sojka Pavilion.

“Bucknell isn’t too far from home,” says Davidheiser, a native of Barto, Pennsylvania, a small town about 50 miles northwest of Philadelphia. “I love the woods. I love fishing and hunting. The wrestling team is great. The professors are great. I’ve developed a family here.”

Davidheiser is a self-proclaimed hard worker who credits his success to that trait. He had a teacher at The Hill School who offered a curriculum where students learned on their own, which was an ideal situation.

“That helped me out a lot,” Davidheiser says. “I was able to figure things out on my own without the help of anyone else, which I have learned this summer is important. Prof. Scott and (labmate) Kevin (Wu) can help me, but I need to figure it out. That’s the way the real world works.”

This is already Davidheiser’s second summer on the Bucknell campus after participating in the Engineering EXCELerator bridge program prior to his first year. He spent four weeks on campus developing his skills in prototyping and fabrication and getting a head start in calculus and physics instruction.

With just 10 weeks on campus this summer, Davidheiser won’t have a robot that will be ready to help with fires and save lives by the end of the term. But, like any engineering project, there needs to be a beginning, and his work is the first step in making safer firefighting a reality.